acoustic Absorption Experimentation

Research on the sound absorption properties of mycelium-based composites.

This research presents a material study that explores how substrate variants and fabrication methods affect the sound absorption properties of mycelium-based composites grown on paper-based waste substrate materials. Samples are grown using Pleurotus ostreatus on waste cardboard, paper, and newsprint substrates of varying processing techniques. Measurements of the normal-incidence sound absorption coefficient are presented and analyzed.

This project outlines three consecutive acoustic tests: the first round of experimentation gathers broad comparative data, useful for selecting materials for sound absorption purposes. The second acoustic test builds on the results of the first, collecting more specific performance data and assessing material variability. The third experiment explores how additional substrate additives affect sound absorption. The results of these experiments are used to inform the design and fabrication of acoustic panels made of mycelium-based composites.

Publications:

Walter, N. & Gürsoy, B. (2022). A Study on the Sound Absorption Properties of Mycelium-Based Composites Cultivated on Waste Paper-Based Substrates. Biomimetics, 7(3), 100. doi: 10.3390/biomimetics7030100

Walter, N. (2023) Mycelium-Based Composites for Sustainable Architectural Acoustics. [Master’s Thesis, Pennsylvania State University]. Penn State University Libraries. https://etda.libraries.psu.edu/catalog/27176nvw5160.

Material Preparation

Material cultivation begins with substrate selection and preparation. The prepared substrates are then sterilized in an autoclave to mitigate contamination. Once sterilized, the materials are inoculated with P. ostreatus mycelium grown on cotton seed hulls and straw (spawn). These samples are left to grow in a controlled growth environment, first in autoclavable bags for 12 days and then in sterile formworks for 16 more days. Once grown, the samples are dried and heated in a 200 °F oven to kill the mycelium and stop the cultivation process. The samples are then shaped to fit into an impedance tube to test for sound absorption.

Testing protocol

Six replicates for each of the samples (material thickness: 38 mm) are tested three times using an impedance tube, specifically the two-microphone transfer-function method, following the standard ASTM E1050-12. Brüel and Kjær’s Impedance Tube Kit (50 Hz–6.4 kHz) Type 4206 is used in this experiment.

Preliminary Mycelium Growth Experiment

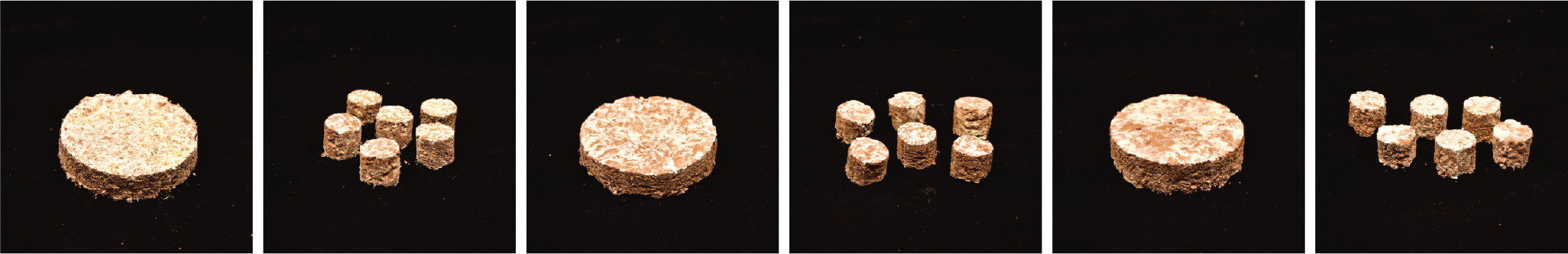

Samples for Acoustic Testing: [From top to bottom rows] (a) Prepared Substrates; (b) Mycelium Mixtures in Formworks; (c) Composite Materials After Drying; (d) Composite Materials after Drying- Side View.

Impedance Tube Tests

The results of Experiment 1 and 2 indicate that mycelium-based composites grown on waste shredded and fine cardboard show potential as sound-absorbing materials, specifically in the mid to high-frequency ranges. Shredded cardboard samples slightly outperform fine cardboard samples in high-frequency ranges. The results of Experiment 3 show similar absorption coefficients between the cardboard, cardboard-sawdust, and cardboard-switchgrass samples, with the cardboard-sawdust material slightly outperforming the cardboard and the cardboard-switchgrass material.